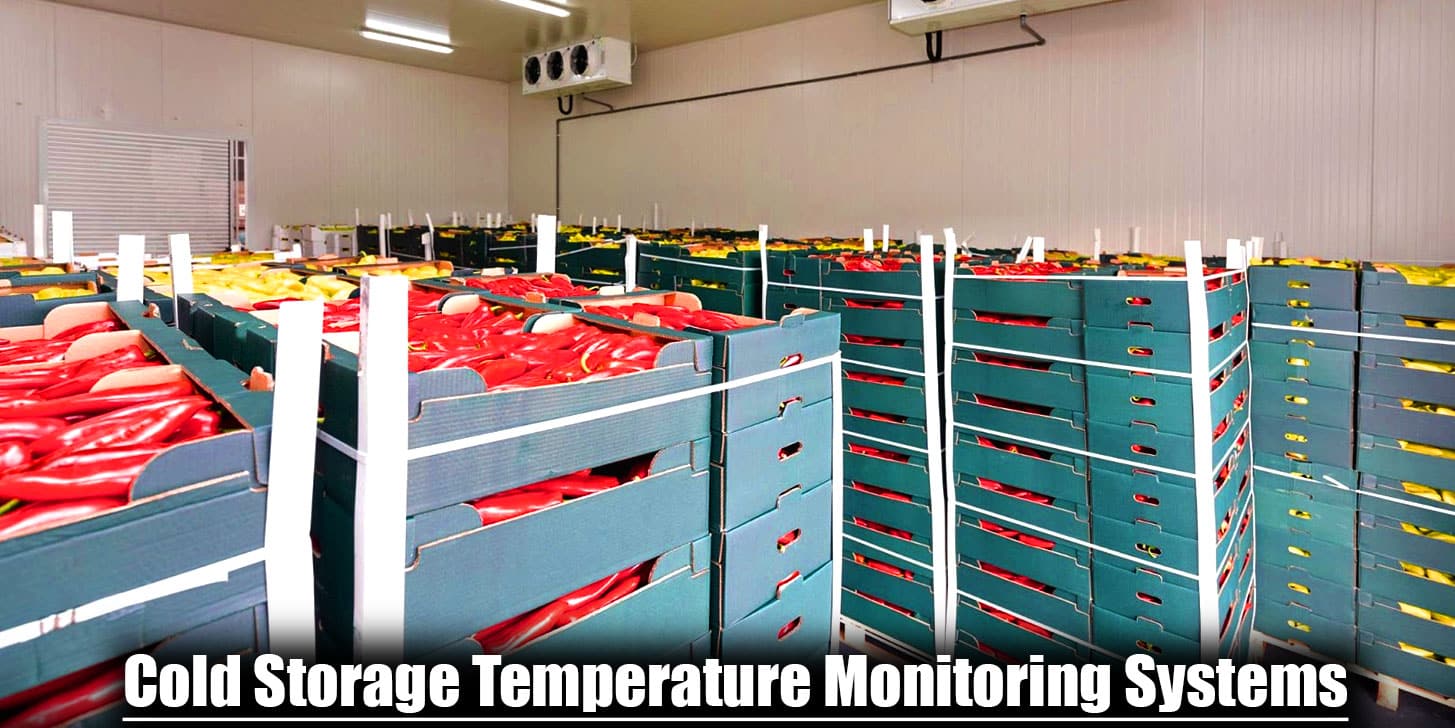

Proper temperature Maintaining is a very important factor not only for safety but also for the quality of perishable food in the ever-changing landscape of food distribution and storage. In order to avoid the spoiling of food products, fresh fruits, and pharmaceuticals, so Cold storage facilities are important. However, because of the number of issues, it is difficult to maintain constant temperature control which may include environmental influences, human error, and malfunctioning equipment. Cold Storage Temperature Monitoring Systems (CSTMS) have become essential instruments for tracking, controlling, and documenting temperature fluctuations in cold storage environments as a result of these difficulties. In this blog, all important factors of CSTMS will be defined, including how they operate, and the advantages that help preserve food quality and safety.

Understanding Cold Storage Temperature Monitoring Systems

A full range of software and hardware products are used in cold storage temperature monitoring systems which are helpful in tracking, regulating, and evaluating the temperature of cold storage facilities. In order to provide current time visibility into temperature changes, these systems make use of complex sensors, data logging capabilities, and communication technologies. This ensures regulatory compliance and maximizes operating efficiency.

Components of Cold Storage Temperature Monitoring Systems

Temperature Sensors

Temperature sensors are the first and foremost and main component of Cold Storage Temperature Monitoring Systems. Temperature sensors are in charge of taking correct temperature readings at different locations throughout the cold storage facility. These sensors are available in many different configurations, such as thermistors, resistance temperature detectors (RTDs), and thermocouples, each designed to meet the demands of a particular application and set of environmental parameters.

Temperature Monitoring Data Logger

Electronic devices having sensors built in to continuously analyze temperature levels and store data at predetermined intervals are called data loggers. The tiny devices are arranged in a strategic manner throughout the cold storage facility to provide an all-encompassing temperature profile. This allows the operators to monitor temperature trends over an extended period of time and detect any possible anomalies or deviations.

Control Systems

The major component of a Cold Storage Temperature Monitoring System is the control system, which allows automated temperature control and control functions. These all systems are fitted with programmable logic controllers (PLCs) that process temperature data in current time from sensors and update cooling systems to maintain ideal temperatures within preset bounds.

Communication Infrastructure

Communication is the key in any field, so the same in the Cold Rooms Temperature Monitoring Systems that allow data transmission and remote monitoring capabilities. The infrastructure in question comprises wired and wireless networks, cloud-based platforms, and Internet of Things (IoT) protocols. These allow operators to check the temperature data remotely and get alerts and notifications at the current time.

Working of Cold Storage Temperature Monitoring Systems

The CSTMS follows the working process that working process is classified into different parts these process is shown below:

Temperature Monitoring

Temperature sensors are arranged around the cold storage facility to measure critical points like product shelves, refrigeration units, and storage chambers. These sensors continuously monitor temperature and provide data for analysis to centralized control systems

Data Analysis and Control

Sensors provide current time temperature data to centralized control systems, which observe it to find any variations from setpoints. Control systems initiate automated reactions to modify cooling systems, control temperature settings, or activate alarm mechanisms to notify operators of possible problems if temperature anomalies are found.

Alerting and Notification

The alerting feature is one of the best features as this is a built-in feature that helps to inform the members by alerting them through the Cold Storage Temperature Monitoring Systems alerting feature. These alerts can be of different types depending upon the requirements. These alerting mechanisms include SMS, email alerts, and loud alarms. With the help of these notifications, operators may minimize product losses and stop spoiling right away.

Benefits of Cold Storage Temperature Monitoring Systems

Enhanced Food Safety

By ensuring constant temperature control and reducing the chance of growth of bacteria, contamination, and spoiling, CSTMS is essential to the protection of food safety. CSTMS reduces the risk of foodborne infections and upholds consumer confidence by preserving the quality and integrity of perishable items by maintaining ideal temperature conditions.

Cost Savings

Cold Storage Temperature Monitoring Systems help minimize product losses resulting from temperature deviations, reducing waste and maximizing the profitability of cold storage operations. By saving spoilage and extending the shelf life of perishable goods, CSTMS delivers tangible cost savings and improves overall financial performance.

Real-time Visibility and Remote Monitoring

Operators in cold storage facilities may remotely monitor temperature levels and react quickly to any deviations or alarms thanks to CSTMS’s real-time visibility into temperature conditions within the facilities. By enabling operators to analyze problems, make educated decisions, and apply corrective actions from any location, remote monitoring capabilities improve operational responsiveness and agility.

Conclusion

There are a number of advantages of CSTMS which help to save food items and another major benefit is that it saves cost by minimizing losses and reducing waste. And anyone can easily understand because of its user-friendly alert and notification.